Sukha launches Welding Machine with Management System and Connectivity that Increases Welding Control

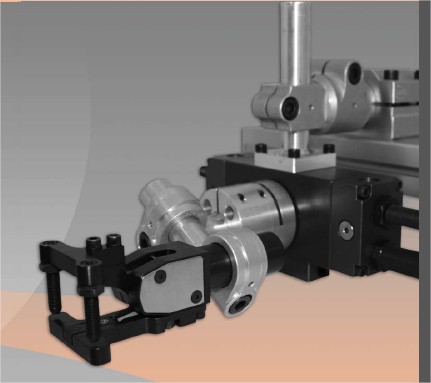

Specialized in the manufacture of welding machines and automation and robotics systems, Sukha launches at Intermach the SPX spot welding machine, equipped with a management and connectivity system that provides greater control of the welding process. The equipment has medium frequency technology that adds a better weld finish and energy savings. It has an anti-crush safety system that complies with NR12, eliminating the need for enclosing, which expands the free area for handling the parts to be welded.

Specialized in the manufacture of welding machines and automation and robotics systems, Sukha launches at Intermach the SPX spot welding machine, equipped with a management and connectivity system that provides greater control of the welding process. The equipment has medium frequency technology that adds a better weld finish and energy savings. It has an anti-crush safety system that complies with NR12, eliminating the need for enclosing, which expands the free area for handling the parts to be welded.

This model of welding machine meets the most diverse applications, such as welding thick plates, wires, and projecting nuts and bolts. It adheres to the demands of the automotive sector, white goods, domestic utilities, two wheels, steel furniture, heat exchangers, tools and electric motors, agricultural machinery and implements. The SPX is a complete resistance welding machine aimed at Industry 4.0.

CUTTING-EDGE TECHNOLOGY IN WELDING MACHINE – NR12

The SPX welding machine was developed with state-of-the-art technology for the demands of customers who demand quality processes. It has characteristics of adjustments in the pneumatic system that allow the activation, first with low pressure and current trip, for continuity identification. This system facilitates the production process, without the need for confinements or barriers that make it difficult to access products with complex geometries (with technical report + ART).

In this way, the force and the welding shot will only be applied when the product is in the proper position, validated by the safety sensor, between the upper and lower electrodes. To meet product size variations, the welding head has manual positioning adjustment. In addition, this system is connected to the safety PLC that monitors the pressure together with the pressure switch and inhibits the safety release of all equipment.

MANAGEMENT AND CONNECTIVITY SYSTEM

The welding machine’s management and connectivity system ensures robustness of the welding process, enabling real-time production monitoring, with inspection/audit/test controls, traceability records, electrode wear and remote access reports to those responsible. , eventual alarms or production stops, for quick response. The digital control plan provides the equipment with offline control functions, where the control characteristics will be monitored in real time, with the necessary records for quality assurance and traceability of the welding process.

The welder’s feedback feature identifies out-of-spec welding current and force, making it possible to segregate out-of-spec parts and provide data for process indicators and their traceability.

ABOUT SUKHA

Sukha is a Brazilian company, specialized in the manufacture of resistance welding machines. It manufactures from standard models (stitching, projection, sewing, top), to customized projects with robotic cells and automated welding centers, developed by the engineering team, according to the customer’s needs.

Companies from the most varied sectors of the industry have already used Sukha welding machines, including Mercedes Benz, Future Utilidades, WEG and AGCO Corporation. In addition to the equipment, it offers personalized technical assistance, training, machine overhaul, adaptation to NR12 with anti-crush system and sale of parts and accessories.